Process engineering - operations research - Machine learning

Historical developments - (design bpm)

Evolution change, documenting

The distance in a flat mapping looks big,

🎭 another dimension:

next door.

To get know what has happened looking into archives is a starting point.

Connect that to what is happening so you can understand the why.

🔰 the most logical

begin anchor.

Contents

| Reference | Topic | Squad |

| Intro | Evolution change, documenting | 01.01 |

| Evolve | What is changing, just thinking | 02.01 |

| | Origin of computerization | 02.02 |

| oneoff | One off proces, immediate running (business proces) | 03.01 |

| optindus | optimalization industrial era (I) | 04.01 |

| devtst | Develop & Test, POC, before running (business proces) | 05.01 |

| infl20_1 | optimalization 20-th century (II) | 06.01 |

| | Changing the world (a) | 11.01 |

| changedev | Change of human influance inventing a proces | 12.00 |

| | Fully human, immediate impact (I) | 12.01 |

| | Delegated but human, validation before change (II) | 12.02 |

| | Computer aided decision making, validation before change (III) | 12.03 |

| infl20_2 | optimalization 20-th century (III) | 13.01 |

| dev-aiml | Machine supported Develop & Test, POC, Run | 14.01 |

| | Changing the world (b) | 15.01 |

| review | Review of my thoughts | 16.01 |

Progress

- 2020 week:28

- Alignment to scientific support conforming math in next door.

- Alignment to new CSS stylesheet.

- 2019 week:13

- This chapter is done fresh, no conversions.

- 2019 week:15

- Changed adding first section contents including back link

- Reordered filling squad´s, reordered text

What is changing, just thinking

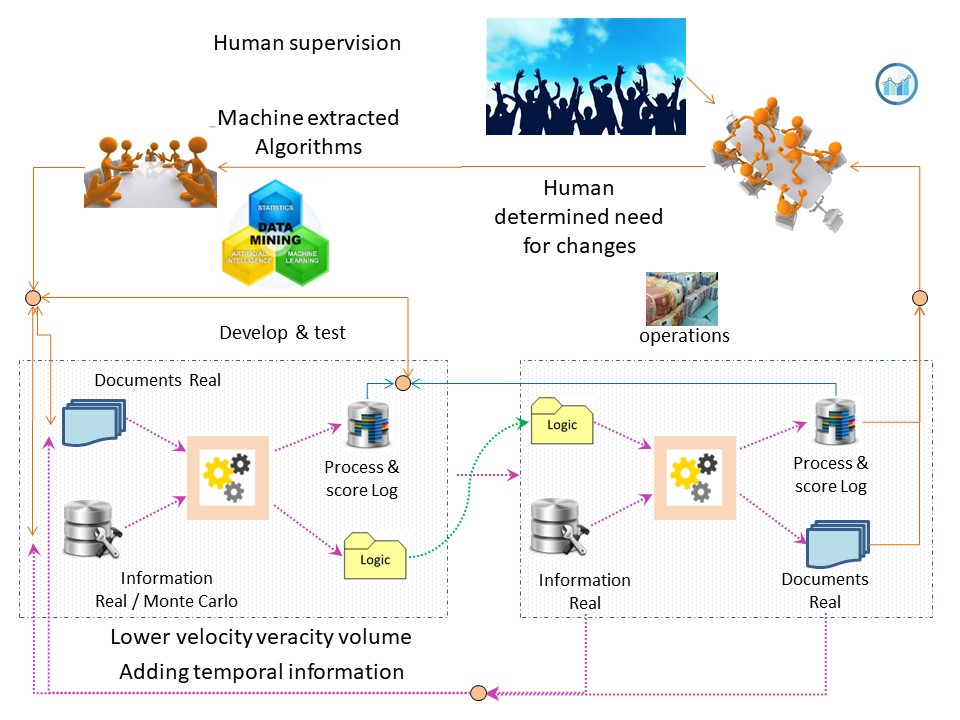

The ICT is transforming into using more ML (Machine Learning), a subarea of AI (Artifical Intelligence). The proces how to implement that is not settled yet.

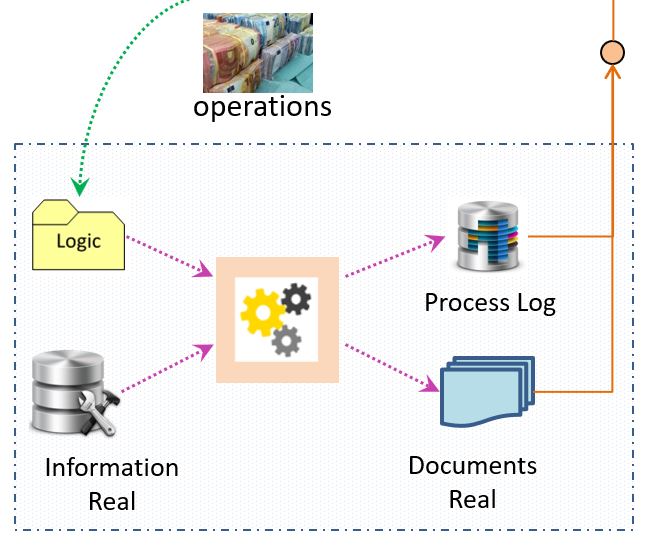

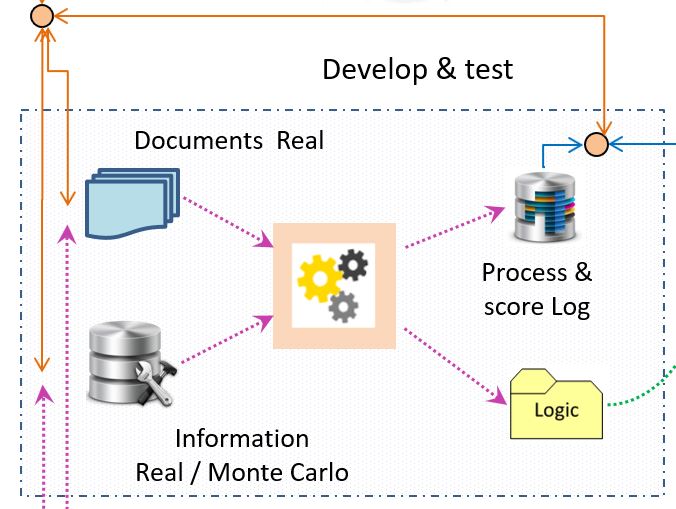

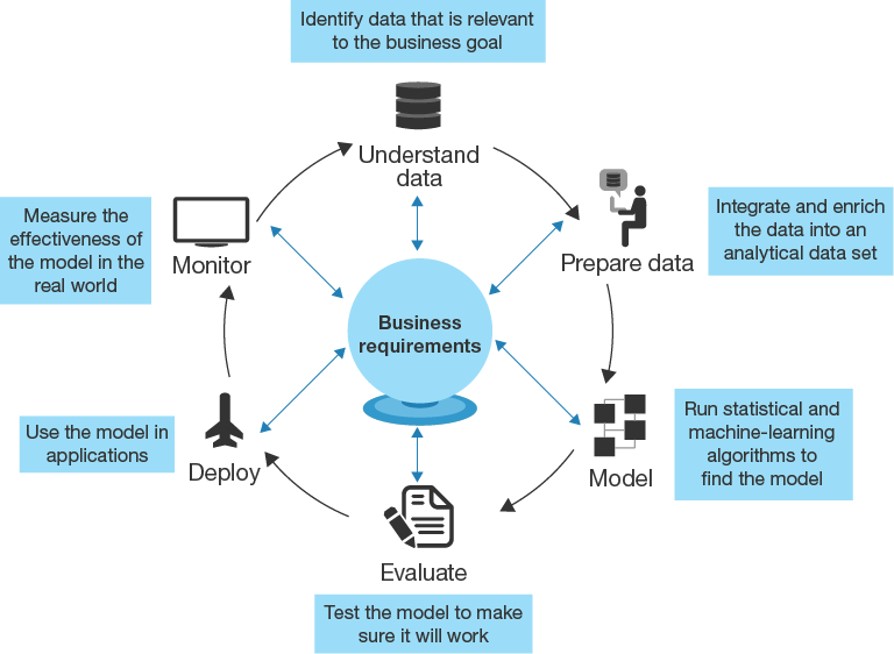

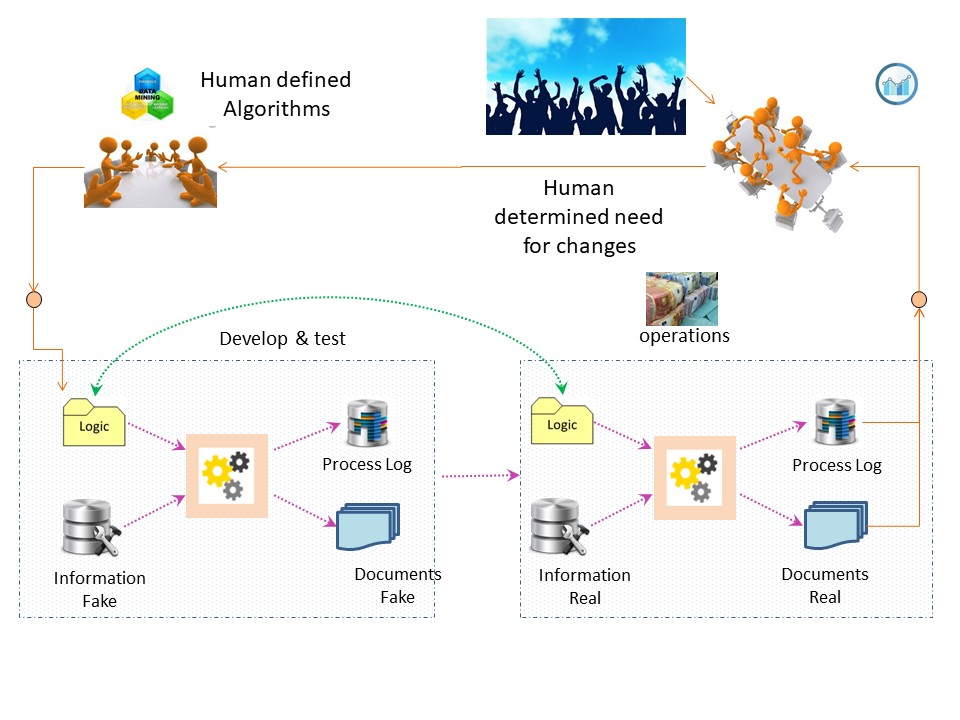

A personal figure is of a ML proces (develop & operations):

It looks very complicated tyring to show the development and operational proces. I will have to explain the steps that have led to this.

This figure doesn´t cover the several stages that are present at development / test at the left side.

Origin of computerization

We are presuming using computers, machines is of very recent years. That assupmtion is not correct.

Optimization of the work force started with the industrialisation.

Programming machines saving on costly hard manual work. The

jacuard loom (wikipedia) was the first example.

With this in mind a lot has changed nobody these days is worried about.

One off proces, immediate running (business proces)

Before ICT was common al lot of processes have been executed. They delivered sometimes marvelous wonders like the egyptian pyramids (physical buildings).

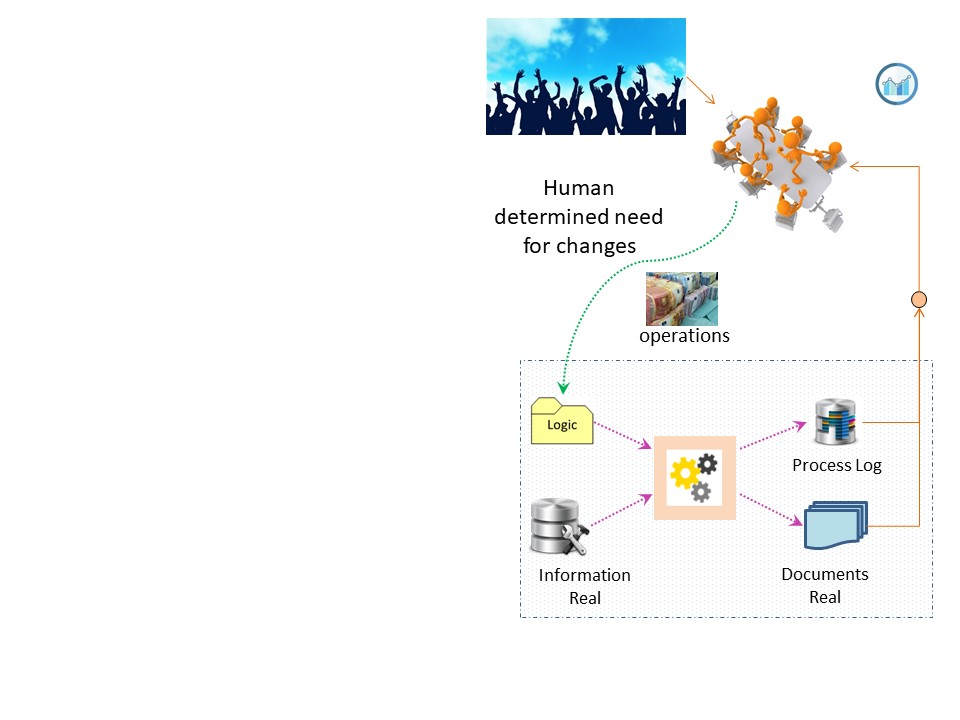

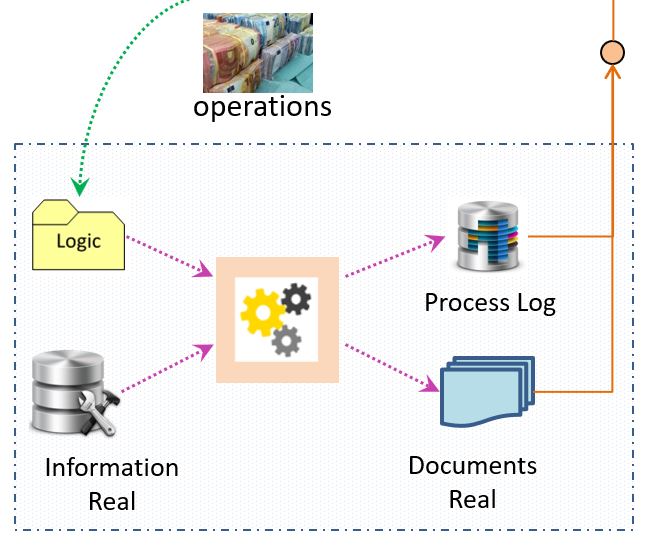

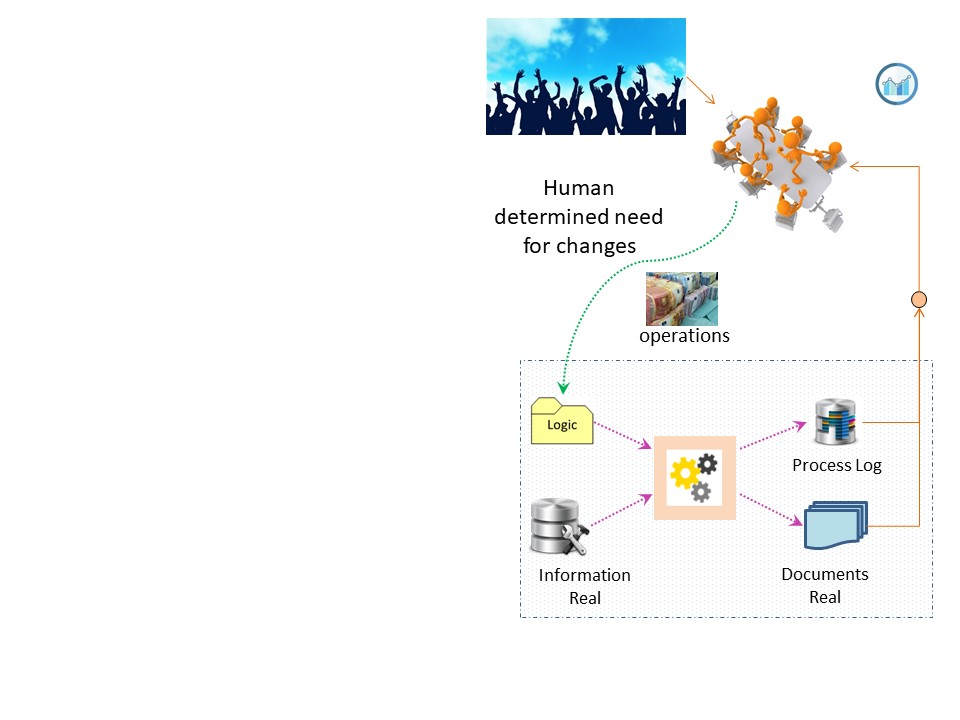

A personal figure is of a classic one-off proces ( just operations):

As one-off nu proof of concept, no development and testing is done. Only knowledge and experience, experiences handed over by teachers.

There are four basic components in every proces, these are:

- Logic = instructions what how and when to do something.

in a physical workd it can be a building plan

- Information = materials, data that is needed in the proces.

In a physical work it can be bricks and other materials

- Documents = The wanted result of the proces.

In a physical world the building

- Logs (scores) = The administration on what has happened, who has to pay the bill an who get paid.

Applicable situations for an one-off

There are a many situations that this is the best approach. Not all projects are clearly one-offs.

In the Apollo project everyting was tested and validated. Only the unforeseen being a problem.

optimalization industrial era (I)

Taylor

Taylor (wikipedia)

Taylor's scientific management consisted of four principles:

- Replace rule-of-thumb work methods with methods based on a scientific study of the tasks.

- Scientifically select, train, and develop each employee rather than passively leaving them to train themselves.

- Provide "Detailed instruction and supervision of each worker in the performance of that worker´s discrete task" (Montgomery 1997: 250).

- Divide work nearly equally between managers and workers, so that the managers apply scientific management principles to planning the work and the workers actually perform the tasks.

⚠ Within the setting of a factory fully control of workers is possible.

This rigid approach of seeing human workers as inhuman robots caused the aversion.

Henri Fayol

Henri Fayol (wikipedia)

While Fayol came up with his theories almost a century ago, many of his principles are still represented in contemporary management theories.

- Division of work = Different levels of expertise can be distinguished within the knowledge areas (from generalist to specialist).

- Authority = gives the management the right to give orders to the subordinates.

- Discipline = about obedience.

- Unity of command - Every employee should receive orders from only one superior or behalf of the superior.

- Subordination of Individual Interest = The interests of any one employee or group of employees should not take precedence over the interests of the organization as a whole.

- Remuneration = All Workers must be paid a fair wage for their services.

- Centralisation and decentralisation = Centralisation refers to the degree to which subordinates are involved in decision making.

- Scalar chain = The line of authority from top management to the lowest ranks represents the scalar chain.

- Order = There should be a specific place for every employee in an organization.

- Equity = Managers should be kind and fair to their subordinates.

- Stability of tenure of personnel = High employee turnover is inefficient.

- Initiative = Employees who are allowed to originate and carry out plans will exert high levels of effort

- Esprit de corps = Promoting team spirit will build harmony and unity within the organization.

Within the mining setting a self management responsible team is required, operating in an dangerous environment.

There is no option for micro-management as the generals keeping away from the most dangerous locations.

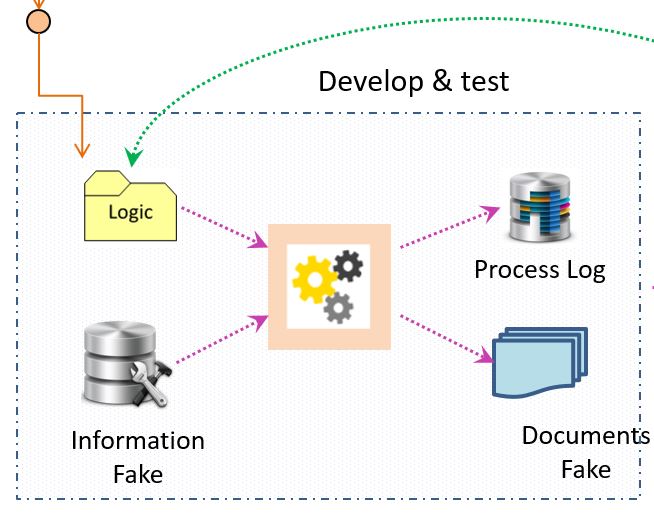

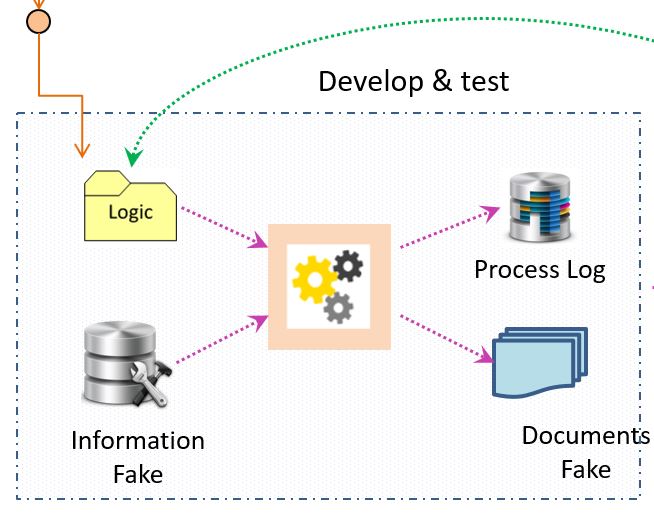

Develop & Test, POC, Run (business proces)

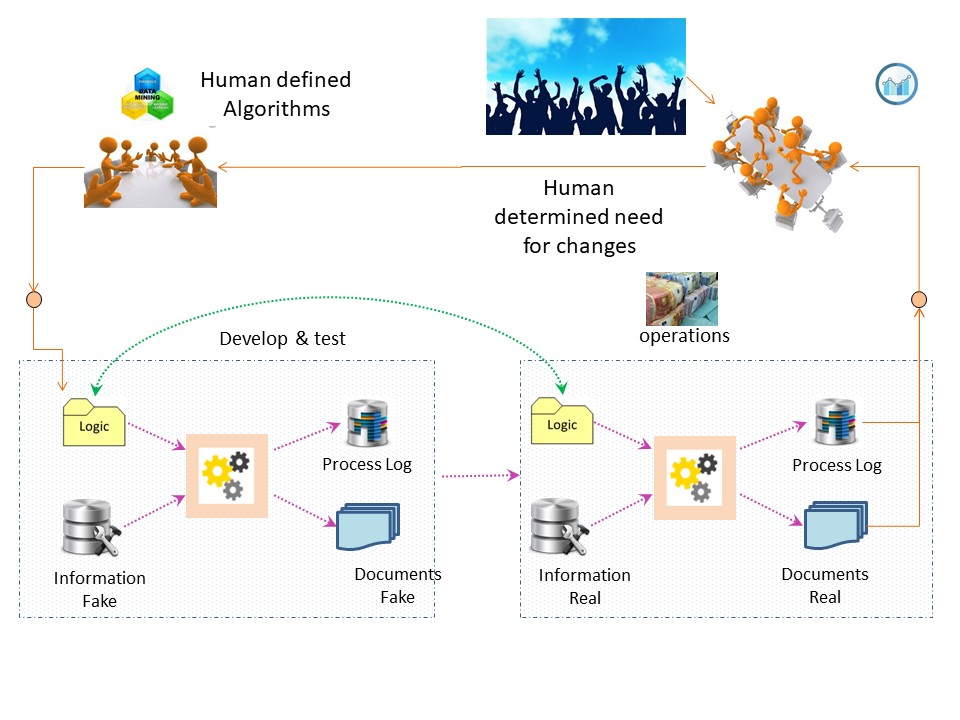

ICT has for many years being operated in a proces model: human defined algorithms. In a develop test environment simulating the operation, no real information.

A personal figure is of a classic one-off proces ( develop, test - operations):

There is a working group placed in the middle between the leaders (top strategy) and the workers (operations).

supporting changes

There are many companies offering an ITIL course. The idea is responding on an event that was not planned.

An Apollo 13 ITSM - game

💣 The goal is acting on incidents. Building and operating in a reliable predictable way is not covered.

Prioritizing would be better avoiding that proces as much as possible.

optimalization 20-th century (II)

W. Edwards Deming

W. Edwards Deming (wikipedia)

The "Seven Deadly Diseases" include:

- Lack of constancy of purpose

- Emphasis on short-term profits

- Evaluation by performance, merit rating, or annual review of performance

- Mobility of management

- Running a company on visible figures alone

- Excessive medical costs

- Excessive costs of warranty, fueled by lawyers who work for contingency fees

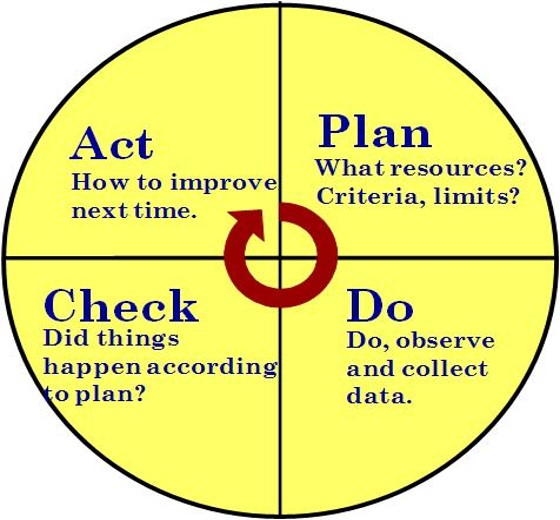

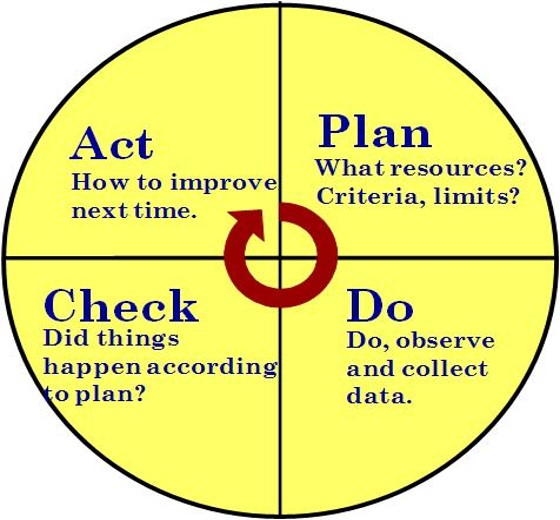

PDCA (plan–do–check–act or plan–do–check–adjust) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. It is also known as the Deming circle/cycle/wheel

Henry Ford

Henry Ford faster & cheaper facturing

Assembly line (wikipedia)

1913 Experimenting with mounting body on Model T chassis. Ford tested various assembly methods to optimize the procedures before permanently installing the equipment.

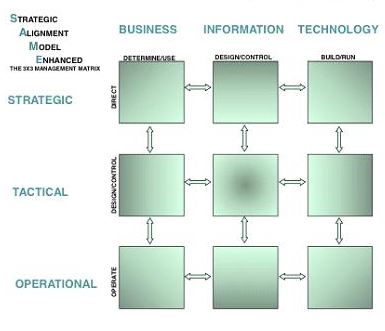

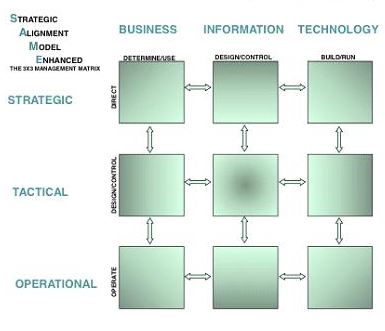

Visie op informatie-management

Visie op informatie-management (AIM Amsterdam Information Model "Amsterdamse raamwerk voor informatiemanagement")

Many see this as a static situation. Often only the strategic level is considered.

Strategies are worthless untill they are adopted by tactical and operational level.

The tactical level needs to define which projects are needed forthe strategy.

On an operational level, the projects have to be implemented and included in daily operations.

The tactical level sets goals and preconditions of the strategic domain into: concrete, realizable objectives, responsibilities, authorizations, frameworks, and guidelines for operations.

Change using information.

Changing the world (a)

optimalization Agriculture

Food production and demand on a global basis, with special attention paid to the major producers, such as China, India, Brazil, the US and the EU.

Agricultural_science (wikipedia)

optimalization your home

A Smart Home is one that provides its home owners comfort, security, energy efficiency (low operating costs) and convenience at all times.

optimalization transport

Logistics Transport (wikipedia)

Change of human influance inventing a proces

Fully human, immediate impact (I)

This is: changing in production.

That can be effectieve when the proces is new and nothing being replaced.

When something unexpected is happening, the delay in delivering as ususal, most nost be problematic.

Delegated but human, validation before change (II)

This is: changing in planned journey´s.

The journey myst be clear. The differnces between the real operation in performance, date settings, connections must get managed.

Release mangement (DTAP) to be implemented.

When something unexpected is happening, fixing must be able bypassing changes already waiting.

Computer aided decision making, validation before change (III)

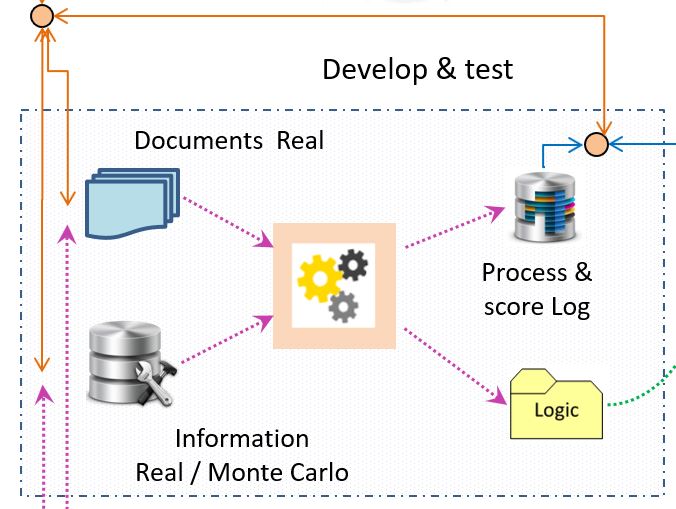

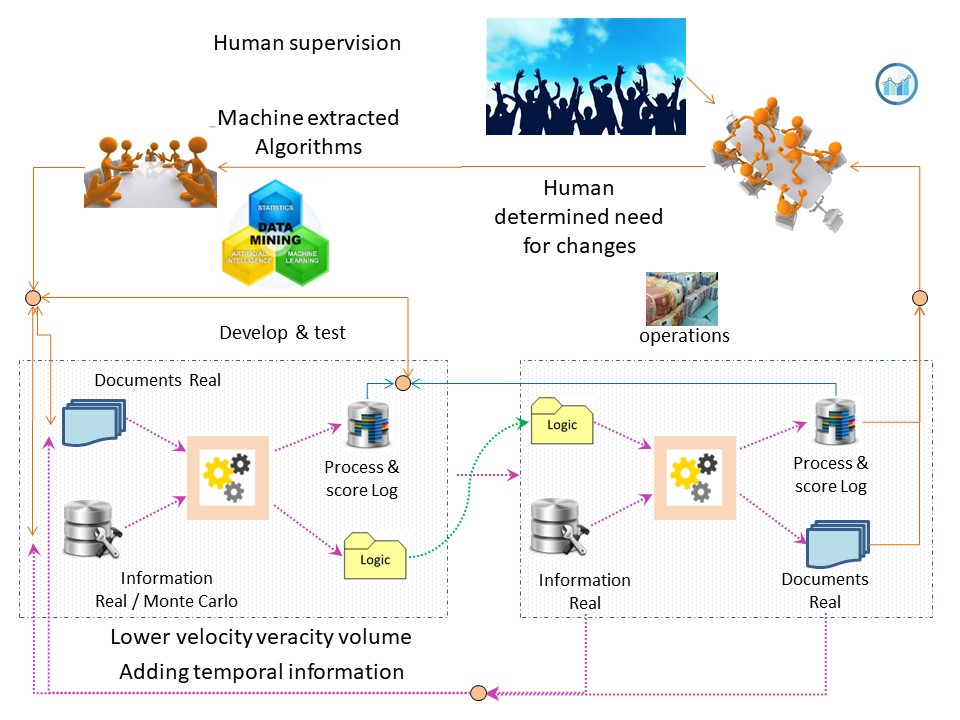

Computer support defining logic, Machine Learning.

An evaluation loop on results, scores, score log, are actions during develop and operations.

Expect the model to behave different in time. Adaptive behavior can be a cause for decreasing results.

optimalization 20-th century (III)

Peter_Drucker

Peter_Drucker (wikipedia)

quotes:

- Management is doing things right; leadership is doing the right things.

- The most important thing in communication is hearing what isn't said.

- The best way to predict the future is to create it.

- Rank does not confer privilege or give power. It imposes responsibility.

- Efficiency is doing things right; effectiveness is doing the right things.

- Unless commitment is made, there are only promises and hopes... but no plans.

- The aim of marketing is to know and understand the customer so well the product or service fits him and sells itself.

- Knowledge has to be improved, challenged, and increased constantly, or it vanishes.

- There is nothing so useless as doing efficiently that which should not be done at all.

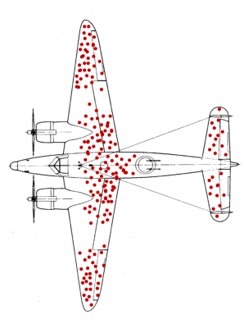

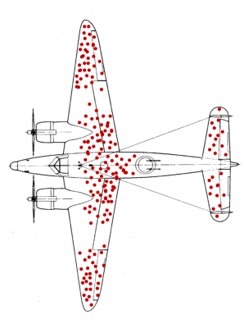

Abraham Wald

Abraham Wald is seen is one of the founders of

Operations research (wikipedia).

Wald noted that the study only considered the aircraft that had survived their missions—the bombers that had been shot down were not present for the damage assessment.

Wald proposed that the Navy instead reinforce the areas where the returning aircraft were unscathed, since those were the areas that, if hit, would cause the plane to be lost.

There are many caviats using Machine Learning. The bias data, the correct meaning data are some of them.

Understanding the uncertaintities, the effect on the whole process but being fair to outlayers are others among a long list.

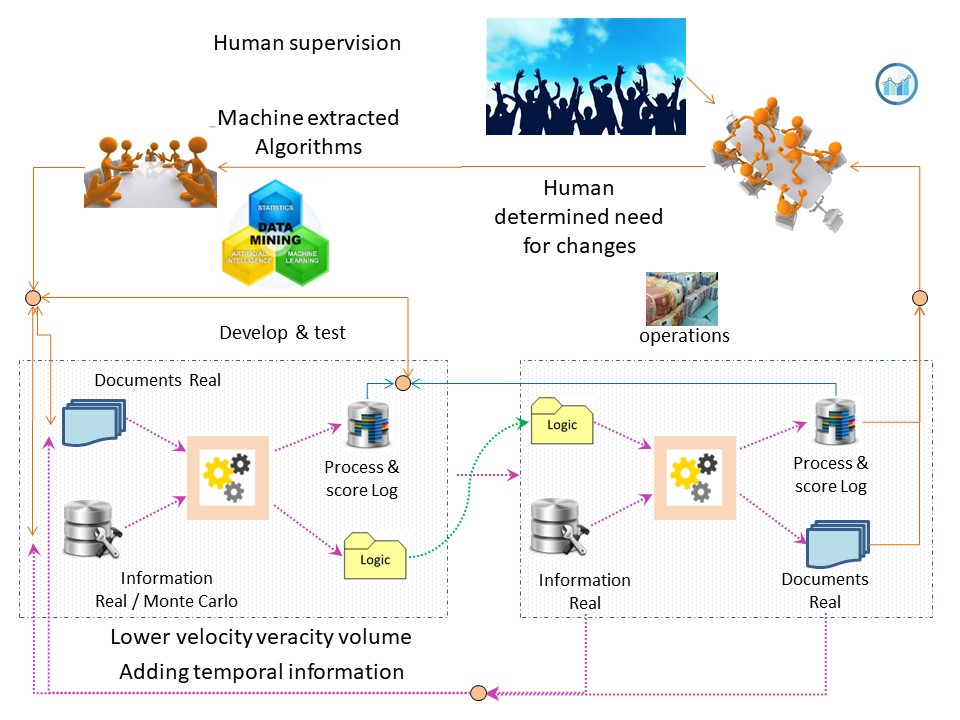

Machine supported Develop & Test, POC, before running (business proces)

ICT has for many years being operated in a proces model: human defined algorithms. In a develop test environment simulating the operation, no real information.

The personal figure of using a Machine Learing proces ( develop, test - operations):

The big change is: the exchange using real documents and real information as input and generating logic.

This approach is only possible with ICT. The special property is being able to make exact copies of operational versions.

Is used at:

👓

threats for data & tools Proces Life Cycle.

Details to be found at:

👓

resulting Life Cycle ALM, business Life Cycle.

👓

Release management SDLC - release management.

Detailed topics are:

- The proces setup (bpm) and getting managed in a Life Cycle.

- Development Test Acceptance Production. Software development, release mamagement, security.

Changing the world (b)

optimalization personal travelling

Travelling (wikipedia)

optimalization decisions

Playing chess is making decisions in a timely manner. with the advice of a machine anyone can beat the master. Note the man behind the computerscreen, he is moving the pieces.

optimalization Health

Health services research (wikipedia)

Review of my thoughts

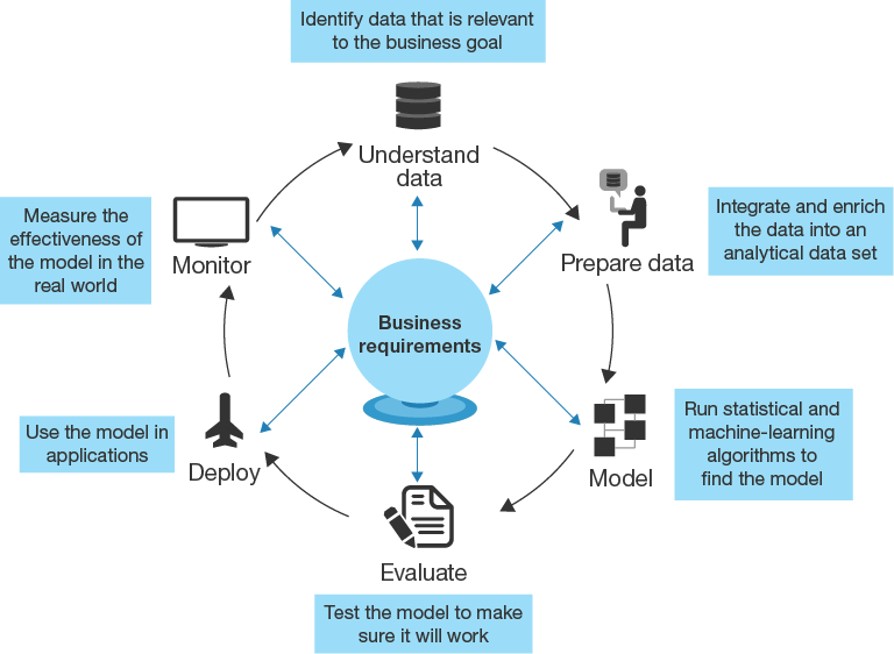

Looking arround what others are posting and what the direction of the opinions is ....

The life cycle is becoming a hot topic (2019). Just modelling, inventing new processes and not able to operationalize doesn't bring the expected value.

There are many more issues to solve than becoming aware of this.

(Picture snapped in a SAS presentation)

analyst viewpoint

Even the life ycle apporaoch is seen:

Many companies still struggle to realize value from predictive analytics despite considerable investments in technology and human capital. This is largely due to the insights-to-action gap, the disconnect between analytical insights and operational processes

Many companies still struggle to realize value from predictive analytics despite considerable investments in technology and human capital. This is largely due to the insights-to-action gap, the disconnect between analytical insights and operational processes

Source:

Close The Insights-To-Action Gap With A Clear Implementation Plan Forrester report (Brandon Purcell 2017)

🔰 the most logical

begin anchor.

The distance in a flat mapping looks big,

The distance in a flat mapping looks big,

There are a many situations that this is the best approach. Not all projects are clearly one-offs.

There are a many situations that this is the best approach. Not all projects are clearly one-offs.

Many see this as a static situation. Often only the strategic level is considered.

Strategies are worthless untill they are adopted by tactical and operational level.

The tactical level needs to define which projects are needed forthe strategy.

On an operational level, the projects have to be implemented and included in daily operations.

The tactical level sets goals and preconditions of the strategic domain into: concrete, realizable objectives, responsibilities, authorizations, frameworks, and guidelines for operations.

Many see this as a static situation. Often only the strategic level is considered.

Strategies are worthless untill they are adopted by tactical and operational level.

The tactical level needs to define which projects are needed forthe strategy.

On an operational level, the projects have to be implemented and included in daily operations.

The tactical level sets goals and preconditions of the strategic domain into: concrete, realizable objectives, responsibilities, authorizations, frameworks, and guidelines for operations.